Artificial Intelligence (AI) as a topic has a reputation of being hard to grasp, and disconcerting, with many questions yet to be answered. Nevertheless, it is currently utilised in fields as diverse as medicine and manufacturing and it’s fair to say that AI is the driving force of the 4th industrial revolution (Industry 4.0). AI has continually progressed since it was first coined by John McCarthy, with relatively recent advancements in Machine Learning and Computer Vision. One of the most exciting advances from our perspective is in the field of AI and product defect detection.

AI revolutionises defect detection in a number of ways. It has the potential to fully optimise the business process and streamline activities, by reducing lead times and increasing all round efficiency. With more and more companies making the shift towards AI, there is an urgency to keep up with this Industry 4.0, in order to avoid Strategic Drift. Despite this urgency there are still organisations that lack this push towards AI, with many professionals doing extensive research into AI but only a fraction actively utilising this technology.

Artificial intelligence for industrial inspection

Scantron has incorporated AI software into our Proscan DDMS, in order to not only keep up with industrial trends but also to ensure we are offering the highest quality of products possible. Specifically, Scantron uses artificial intellogence to look for, and characterise, defects on a component. Defect detection is fully automated and runs in real time. Unlike an operator, the process is 100% repeatable and never suffers from fatigue.

Using AI to spot defects with visual inspection

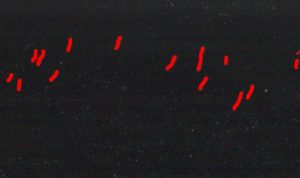

The AI is trained by a human operator skilled in how to detect defects on diverse surfaces. The operator supplies defect detection example images (see figure 2) to the AI software showing the type of defects they wish to discover. This enables the AI software to identify and categorise defects successfully as well as disregard readings triggered by dust or dirt.

This is a typical image where the AI can learn to recognise a defect, or in this case the scratches (figure 1).

Figure 1: defect detection using deep learning

Once the type of defect has been labelled on a training image (Figure 2).

Figure 2: Ai and product defect detection

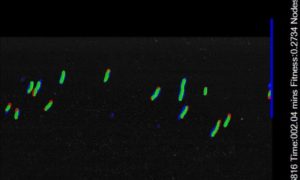

The AI is then able to identified defects that fall under this category (Figure 3).

Figure 3: AI spots defects with visual inspection

How artificial intelligence to identify product and equipment defects works

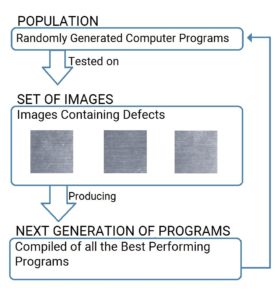

The AI uses a bio-inspired technique called genetic programming, a type of automatic program synthesis, where computer programs are evolved in order to find a solution to a problem. The basic algorithm is very simple, and is based on the principles of Darwinian evolution.

Below is the basic cycle that the AI deep learning software follows when tasked with defect detection:

| 1. We start with a set (a Population) of randomly generated computer programs. |

2. We test each program on a set of images to see how well it does at the Defect Detection Task. |

|

3. Then, we take the better performing (Fitter) individual programs and use these as the basis for the next generation of programs (reproduction with recombination and random mutations). |

Similar to how a computer vision expert might work, the generated programs are comprised of a mixture of high-level image operations and basic mathematics. This has the benefit of allowing the expert to analyse the generated program and check for correctness and robustness – something that is hard to achieve with classical approaches such as neural networks.

Being able to understand the process increases confidence that the correct solution has been found. However, inspection of the output is not always necessary as for many cases; no expert knowledge is required given that the operation of the AI to detect defects on diverse surfaces can be verified by testing on previously unseen data.

To summarize, the automated AI defect detection software:

- Has no need for programming

- Has little need for domain knowledge

- Can learn to ignore readings triggered by dust/dirt

- Is taught by example

- Uses rapid learning

The use of this software to identify and categorise a defect enables companies to achieve a seamless process; giving the luxury of a more reliable outcome which will inevitably have a positive effect on their bottom-line.

To find out more about how we are using artificial intelligence for defect detection and the Scantron Proscan DDMS, contact us.