Wire

Precision online diameter measurement of wire | Cable production monitoring

Scantron brings over 35 -years of experience, handpicked products and best in class bespoke non-contact surface measurement system development, to the wire industry.

We favour Aeroel equipment for precise diameter measuring and offer a range of precision online systems for wire, hose and cable production monitoring, with industry-leading accuracy. Aeroel’s in-line laser micrometers improve process efficiency.

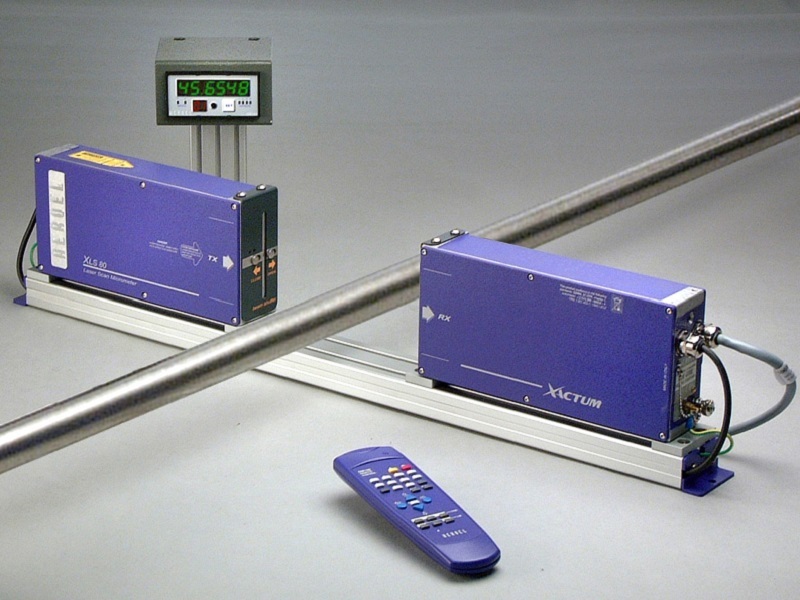

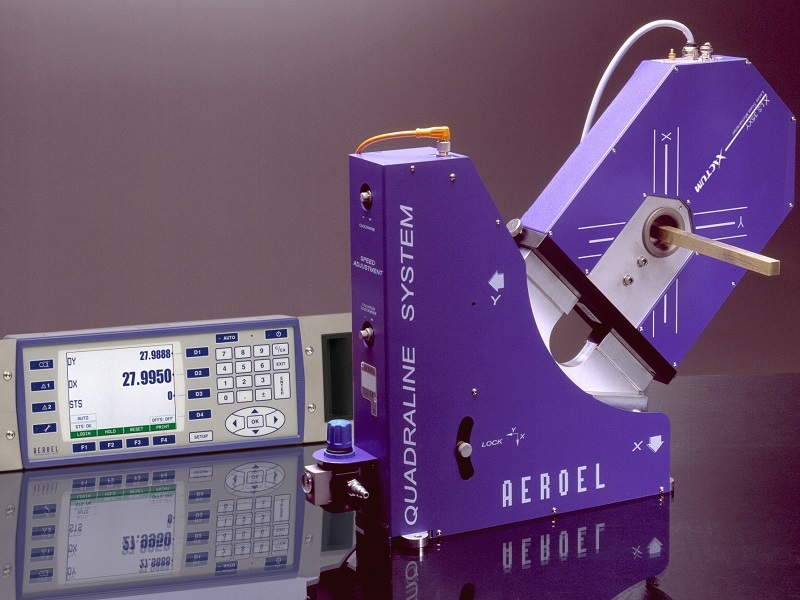

100% quality control of diameter and ovality as well as online feedback for extrusion onto cable can be achieved using Extruline. The high accuracy of the gauges allows fine control of the finished thickness for wire, hose and cable products, working at bottom tolerance to save on raw materials, reduce scrappage and maintain consistency.

Wireline is designed to monitor diameter closely for fast-moving wire and inform the operator on die wear at the earliest point to avoid wasted product. Aeroel’s in-line laser micrometers can be complemented with spark testers or other supplementary systems.

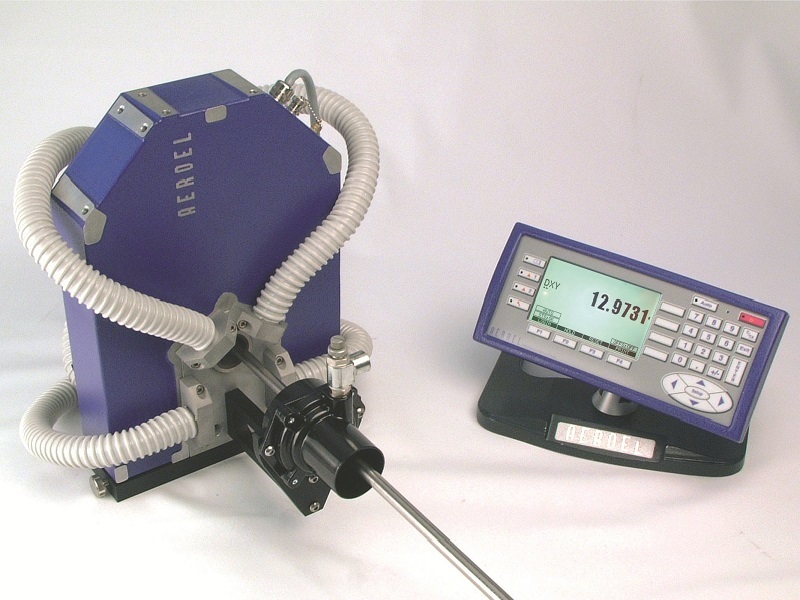

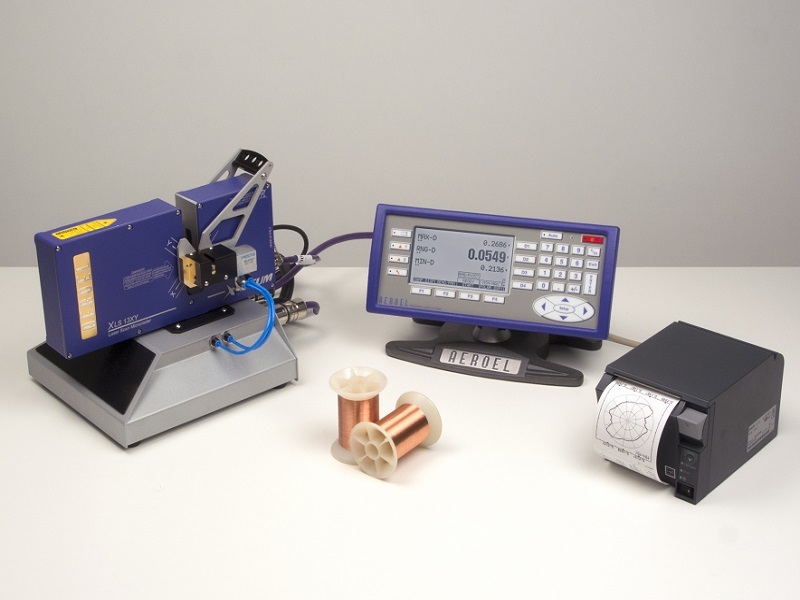

Offline systems for the benchtop or metrology lab are also available. Wirelab and Super-Wirelab allow complete 360° measurement of a wire shape, allowing experienced quality personnel to identify specific issues by examining the shape of the cross-section in sub-micron detail.

Please contact us for more information about any of these products or bespoke solutions for wire, hose or cable.