Scantron has been awarded an Innovate UK grant as lead organisation on a £395k project over two years, in conjunction with the University of Southampton. The project will focus on the examination of bearings from trains. Bearings are in all moving parts from automobiles to aircraft, production machinery and wind turbines. They deteriorate with time and usage through rolling contact fatigue (RCF). Currently bearings are replaced during maintenance schedules (on-time) or when a bearing has failed.

Condition monitoring has been applied for years in many industries and is capable of flagging a change in condition in-service, but not yet capable of quantifying the severity of that damage, sometimes leading to premature extraction. Scantron will develop a tool (the BEARING-EYE system) able to map and interpret the surface damage observed in failing bearings based on the RCF expertise of the University of Southampton.

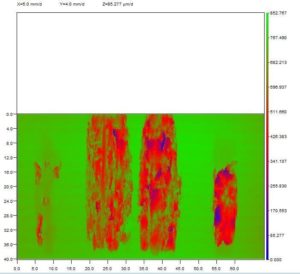

An innovative and intelligent software based on fractographic analysis – the examination of failed bearings – will be developed to interpret the damage severity and report this as a simple numeric output. BEARING-EYE will be an easy-to-use bench-top system that could be operated by maintenance staff to correlate the damage found in bearings with the associated condition monitoring data, to help understand problematic routes and routines. The BEARING-EYE will help determine how long bearings could be left running safely thus avoiding unexpected failure and machinery down-time, and also increase the safety of rail travel. This will also change maintenance programs from ‘on-time’ to ‘on-condition’.