Defect Detection

Automated smart defect detection by Scantron

With 40+ years’ experience at the forefront of the non-contact measurement solutions market, Scantron is uniquely positioned to offer best in class automated smart defect detection. Our solutions are built around a very real understanding that surface quality and appearance of a finished product or critical internal component are highly important.

Bespoke solutions to complex problems across a range of industries and product/component types

We have developed bespoke, cutting-edge solutions to automate, streamline and make the process of defect detection and measurement more efficient, precise and accurate using the very latest technology.

Scantron offers a unique technology to automatically locate, detect and measure defects or imperfections on parts. We harness a combination of machine learning vision systems and optical metrology methods, backed by years of first-hand experience.

We use an intelligent lighting system, in conjunction with a high resolution camera, to precisely determine the locations of the defects. They are then scanned in turn using a high performance chromatic sensor.

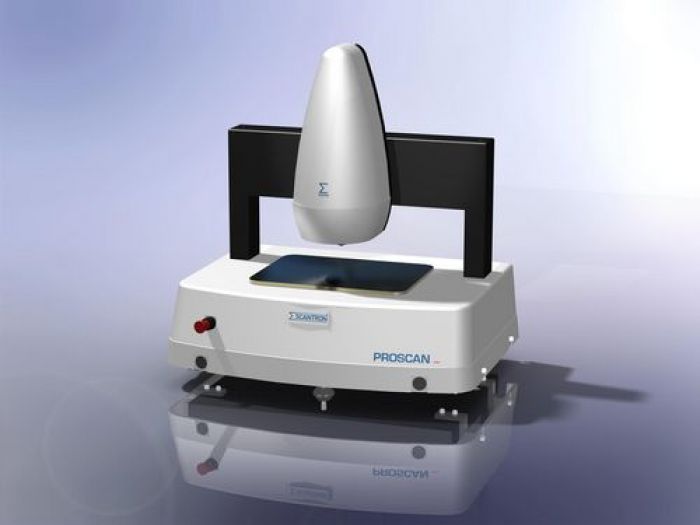

The Proscan Automatic Defect Detection and Measuring System (DDMS)

Our automated defect detection and measuring system (DDMS), developed to revolutionise defect detection, using the latest non-contact measurement technology and advanced machine learning and artificial intelligence (AI) to both identify and measure any type of defect, including scratches, pin holes, material deformities and pits.

For more information about Scantron DDMS, please see the related products below or contact us to find out more.

Proscan 3D Line

Defect Detection and Measurement system for extruded material. The system is capable to take in excess of 1 million measurements per second to micron resolution.

DDMS Line

Defect Detection and measurement System for metal surfaces capable of picking up defects of microns size at a speed of in excess of 1 million measurement point per second.