Proscan Magnum

Proscan Magnum for profile and flatness measurement

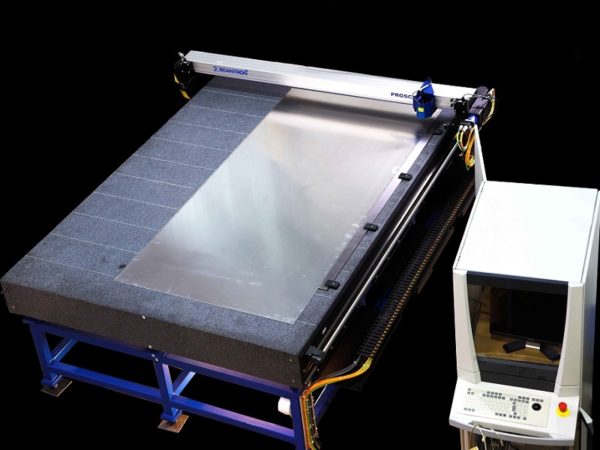

The Proscan Magnum is a non-contact shape table for offline measurement of flatness or shape of aluminium or steel strip. Stresses within the rolled strip mean a residual ‘shape’ remains within the material. This shape is evident when the strip is laid on a flat surface.

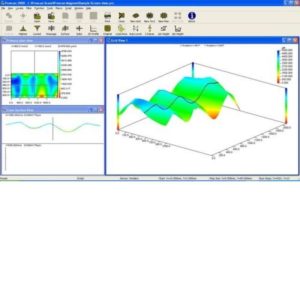

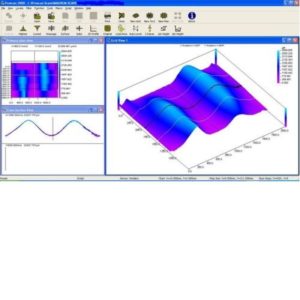

The Proscan Magnum accurately measures and quantifies the latent shape in the sample proving absolute values of wave heights, waves per meter and ‘I’ units. Offline measurement is the most accurate method of measuring shape as there is no tension or stress in the material during the measuring process. This makes the Proscan Magnum particularly suited for measuring thin gauge material with very high flatness specification such as lithographic aluminium coil. This system provides the user with full 2D & 3D mapping of the surface flatness.

Proscan Magnum Measurement Technique

By means of a precision gantry system a laser measuring the sample height is scanned over the surface. For every X & Y co-ordinate position, a height measurement (Z) is taken. The resultant X,Y,Z data file is used to calculate the surface shape. The shape is quantified by calculating the ‘I’ unit for each longitudinal scan.

Scantron has developed a number of Proscan products, including solutions for defect detection and measurement and supported by dedicated profilometry software.

If you need a bespoke non-contact measurement system for profile and flatness, get in touch with us – with more than 40 years’ experience, we are perfectly placed to develop custom solutions across multiple industries and products.

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An EnquiryDownloads

| Surface Table | |

| Length | 3000mm |

| Width | 2100mm |

| Working height | 945mm |

| Thickness | 260mm |

| Flatness | Grade 2 (54µm over table) |

| Air release grooves | 10 grooves across the width |

| Material | Natural granite |

| Weight | 5090kg |

| Support Stand | |

| No of Legs | 12 |

| Construction | Fabricated steel - painted |

| Levelling adjustment | Yes |

| X Axis | |

| X travel | 2200mm |

| X speed | 800mm/sec |

| X encoder | Optical linear encoder 10µm |

| Drive motor | Servo |

| Drive type | Precision ground ball screw |

| Y Axis | |

| Y travel | 1800mm |

| Y speed | <800mm/sec |

| Y encoder | Rotary |

| Drive motor | Servo |

| Drive type | Toothed belt |

| Laser | |

| Measuring range | 50mm |

| Stand off | 70mm |

| Resolution | 0.005mm |

| Linearity | 0.04mm |

| Light source | Visible red |

| Laser class | 2 |

| Maximum output power | 0.95mW |

| Sample rate | 2500Hz |

| Cubicle | |

| Dimensions | 600w x 836d x 1700h mm |

| Services | |

| Supply | Single phase 240VAC, 50Hz, 20A |

| Air/Water | Not required |

| General | |

| Scan cycle time (5 length scan on 2100 x 1800mm sample) | Appx. 25 secs |

| Sample thickness (typical) | 0.05 - 5mm |

| Total weight | 6000kg |

The Proscan Magnum is an accurate, effective and durable solution for the offline measurement of profile and flatness. Benefits include:

- Accurately quantifies the latent shape in samples providing absolute values of wave heights, waves per meter and ‘I’ units

- The most accurate method of measuring shape as there is no tension or stresses in the material during measurement

- Provides user with graphic 3D & 2D mapping of surface flatness

- Quick and fully automatic measurement cycle, complete sample measurement and analysis in less than 20 seconds

- Standard table accommodates samples of 1950 x 3000mm in size with a scanning area of 1800 x 2200mm

- Integrated width gauge (optional)

- Logging of measurement results to user configurable database fields

- Based on Scantron’s proven Proscan 2000 profilometry software

- Fully integrated light guarding system for maximum safety

- Proven Turnkey solution, get the full benefits from day 1 of installation

- Flush top design means easy loading/unloading of samples

- Suitable for other types of sheet material where flatness and shape have to be accurately quantified

- Flatness measurement of any strip product where wave height, wave length and/or I-units need to be measured

- Built-in vernier width gauge

- Larger/smaller table sizes

- Sine wave reference master with calibration certificate