Surface Profile

Specialist systems for profile and shape measurement

Board and web industries require to accurately measure the width, surface condition, shape and flatness of boards/panels online or offline. We have been helping clients measure the profile and shape of board and web products since 1981.

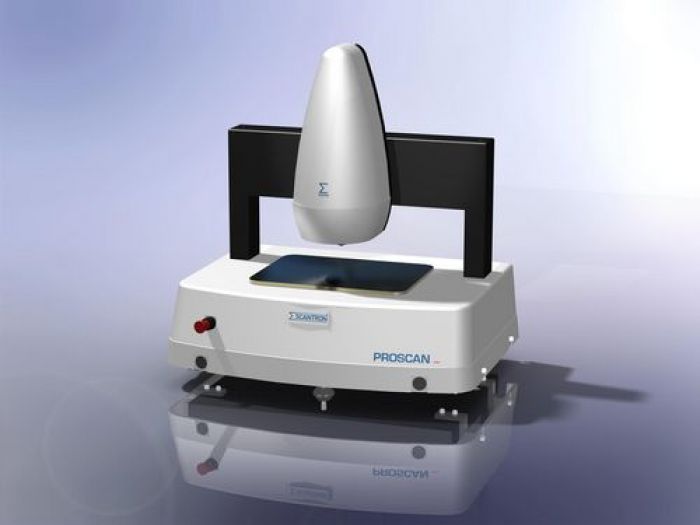

Scantron’s MasterTrak system offers the capacity to measure thickness, width and/or profile of products such as textured or profiled panels and boards. This helps to provide real time feedback to inform operators, or provide process automation. The MasterTrak can be developed with customised geometry and software to tailor it to a specific production requirement.

Applications for the MasterTrak have included insulation foam, profiled panels, thin foam, flat extruded products, strip and screen print production. The system can provide complete measurement and tolerance comparison on width, thickness, profile, edge condition and more, with the geometry of the system tailored to your specific production requirements.

Accurate profile measurement during production

Our scanning technology allows for non-contact profile measurements to be obtained even during the production process.

For example, for manufacture of interlocking cladding panels, a consistent and accurate side profile is critical to ensure good fit and separation during mounting to the exterior of buildings. Scantron’s non-contact profile measurement can be used in this case during production. Using MasterTrak, the measured side or top profile can be compared to the CAD model in real time with deviations reported to the operator. A product library-based approach makes the task of setting up the system effortless with no remastering or manual set-up or adjustment of the system needed.

MasterTrak also features a self-calibrating and remastering technology and several engineering innovations to maximise stability of the frame and minimise thermal drift.

The software layout, display and processing can also be adapted to the requirements of the operators and quality staff. Please get in touch to find out more or visit the MasterTrak page for more information.

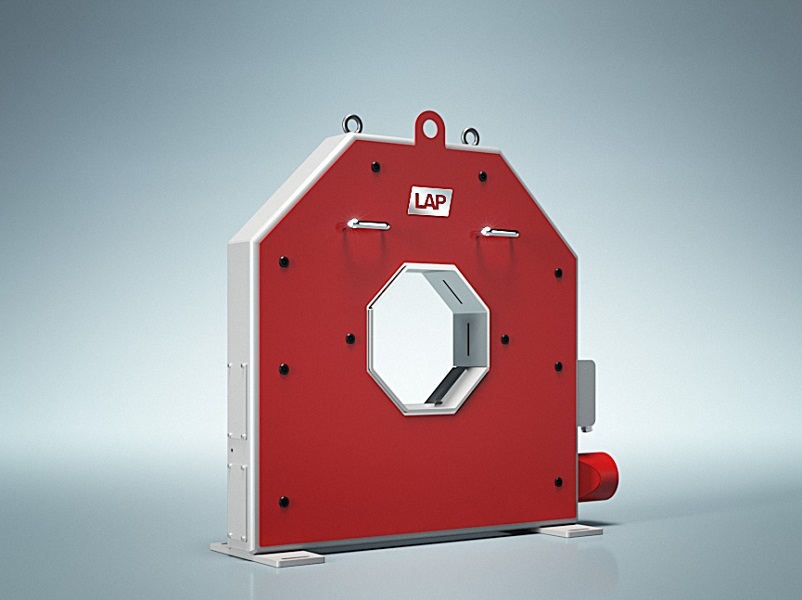

Cross-sectional measurement for complex shapes

Our Contour Check systems offer a complete cross-sectional ‘light-sectioning’ measurement solution for complex shapes and profiles in hot environments; wire, rods, bars and tubes.

Contour Check can be used to accurately measure a range of shapes including rounds, rebar, squares, flats, hexagons, L, U, T or H-shaped bars and profiles. Tri-lobed defects are easily determined as well as rolling defects such as underfill, overfill or shift, eliminating the need for sample cutting. Conditions are immediately displayed and the symptoms are identified to the operator, removing ambiguity and guesswork. A substantial cooling and air-purge system maintains the thermal stability of the system and allows measurement in aggressive environments. For more information, please visit the ContourCheck Page.