Offline Precision Measurement

Offline Precision Measurement Solutions

Scantron offers a number of offline precision measurement solutions for accurate non-contact surface measurement across a range of applications and industry types.

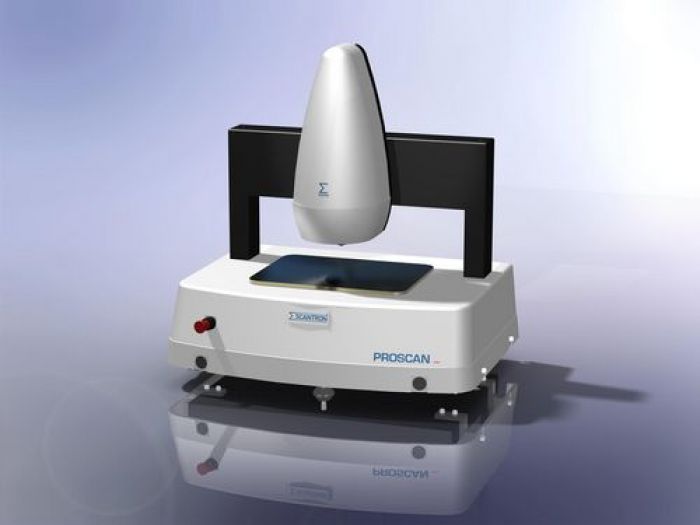

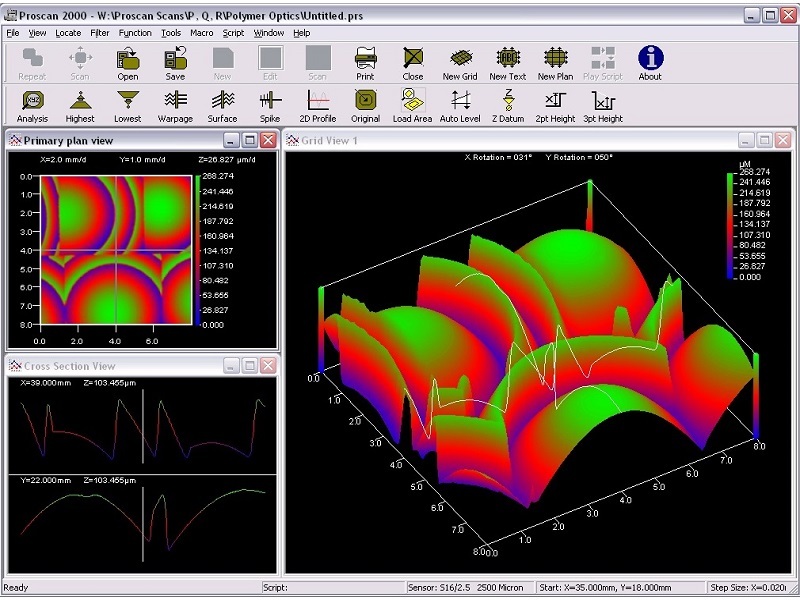

Proscan 2100 profilometer

The Proscan 2100 profilometer offers an accurate and rapid non-contact measurement of shape, form, flatness waviness or roughness for samples of virtually any description, from thin transparent parts to rough metal. Each Proscan 2100 is equipped with one or more chromatic aberration sensor, and can be tailored to match research or production requirements.

The Proscan 2100 can be a direct replacement for a tactile or stylus-type profilometer and is also capable of measuring on soft materials where the stylus can cause scratches and influence results. The rapid measuring time of the Proscan is also an advantage compared to contact systems, which makes it an ideal solution for general purpose metrology or measurement of product defects. The granite structure resists vibration and thermal change to allow full performance of the system in a factory or laboratory environment.

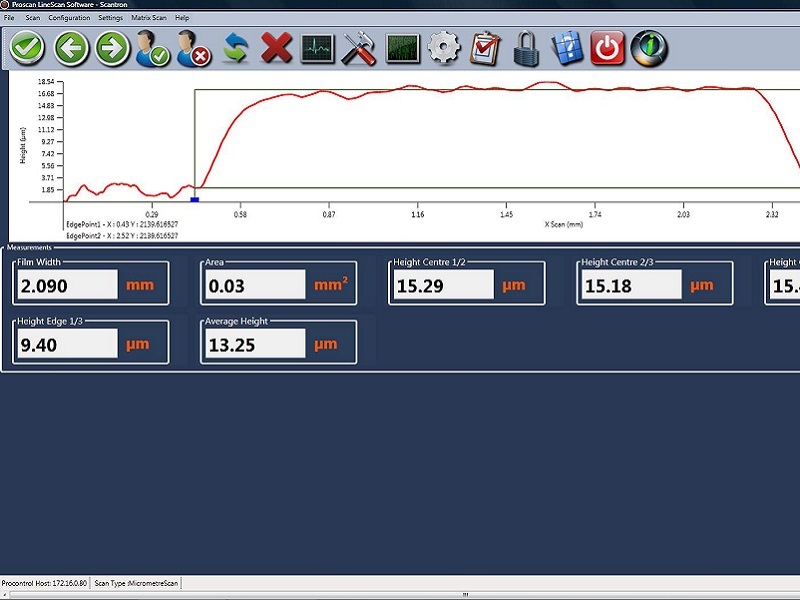

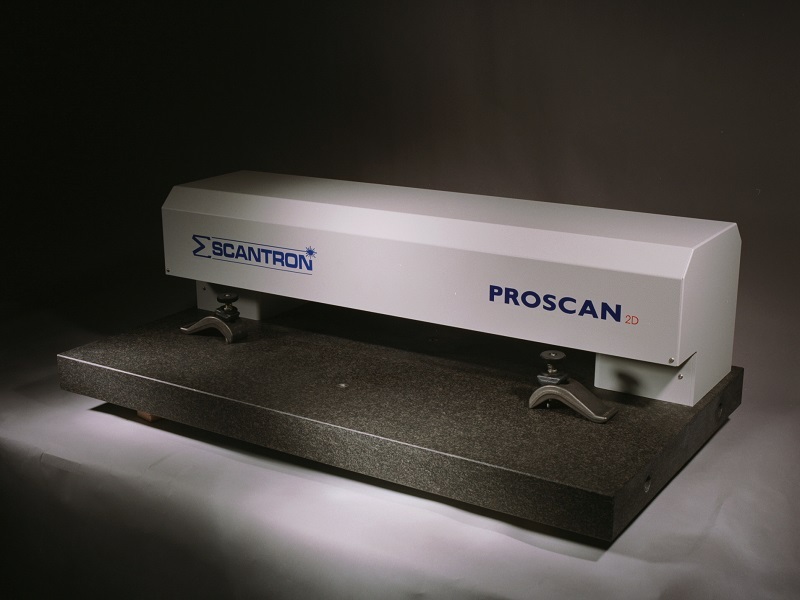

Proscan 2D single-direction profilometer

The Proscan 2D is a single-direction profilometer to quantify product height, width, roughness or flatness very quickly and accurately in a factory environment. Typical applications include gypsum boards, plasterboard, foam or textile. The Proscan 2D scanning length can be tailored to a specific product width or length. Additional software is available to perform complex measurement scripts for profiled or tapered boards, where some portion of the product profile has to be assessed separately.

Like the Proscan 2100, the Proscan 2D precision non-contact measurement system is built with a full granite structure; it is at home on the factory floor or in the metrology room.

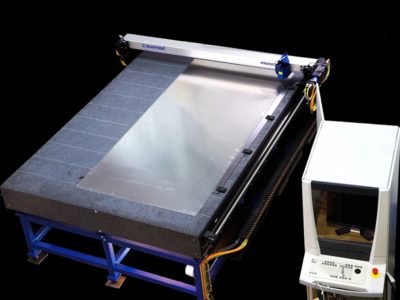

Proscan Magnum for flat shape non-contact offline precision measurement

Proscan Magnum is a shape table developed for the lithographic industry, but ideal for any flat products with high tolerances such as heat exchange plates. Aluminium strip can exhibit edge or centre buckle depending on the tension during the rolling process. The standard Proscan Magnum is a 3.5 by 2.5 m granite table with negligible run-out, to allow precise offline measurement of all dimensions of large sheet, strip, or panel, as well as flatness, I-units, buckle and edge length. Air release grooves are designed specifically to a material and machined into the granite surface to allow the material to settle, avoiding asymmetrical pressure build-up. The scanning gantry moves over the table surface at very high speed allowing for rapid measurement of large products.

Scantron can also develop customised Proscan Magnum sizes for products of various dimensions.

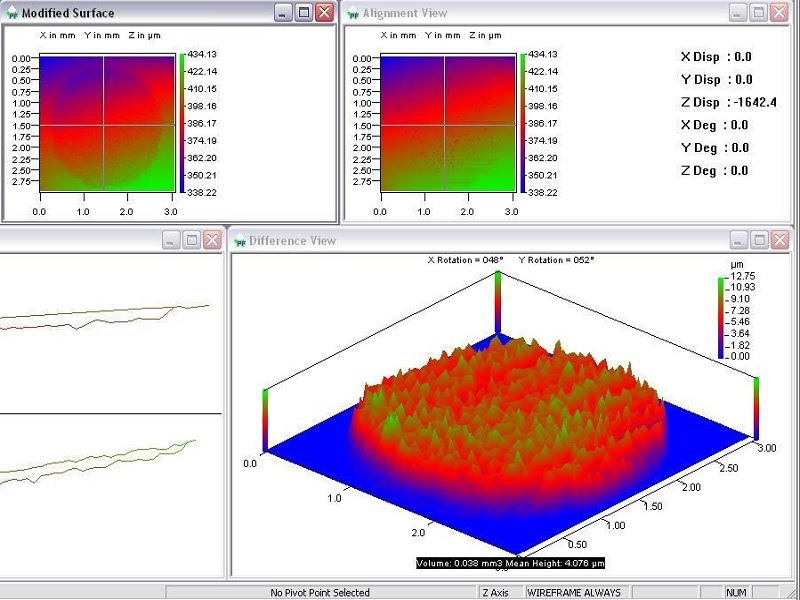

Proscan Defect Detection and Measurement

Proscan DDMS (Defect Detection and Measurement System) is the ultimate in automated material inspection for critical components. Built completely bespoke to a target measurement task, the system will detect defects or inconsistencies in a product with an artificial intelligence (AI) vision system whilst ignoring ‘false flags’ such as dust. It will then automatically categorise and measure the located defects with a high resolution sensor. Commissioned systems exhibited 100% repeatability of defect detection, as well as sub-micron reproducibility. The Proscan DDMS comprises a thick granite table mounted on air bearings to isolate it from vibration.

| Category | Application |

| Proscan 2100 | 3D Roughness, shape, flatness, shape or general inspection |

| Proscan 2D | 2D Roughness, shape, flatness, bow height or width |

| Proscan Magnum | Large flat products – lithograph, strip, panel etc |

| Proscan DDMS | Automated defect detection and measurement, roughness, flatness |