Proscan 2D laser profilometer

Measurement of roughness, flatness, shape, width, taper and bow on boards, panels and strip

The Proscan 2D surface profilometer is a fast, accurate, non-contact 2D profilometer, used in a broad range of applications and useful for detection of sub-par products before they make it to the customer.

Developed by Scantron, the Proscan 2D is a popular solution with clients looking for a non-contact solution for offline sample inspection. It facilitates the measurement of roughness, flatness, shape, width, taper and bow on boards, panels and strip.

The Proscan 2D surface profilometer is an essential addition to any production environment where the analysis of a surface is critical to the performance, productivity or yield of the product.

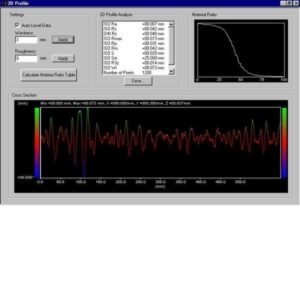

Calling on 30+ years experience, the Proscan 2D combines the very latest in non-contact displacement sensors with sophisticated and easy to use software.

We have a number of other surface profilometer solutions available and can build bespoke systems to suit your specific requirements – contact us to find out more.

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An EnquiryDownloads

| Sensor Model | Measuring Range | Stand Off mm | Resolution | Linearity (% +/- of range) | Technology |

| S3/011 | 110µm | 3.3 | 5nm | 0.1 | Chromatic |

| S11/03 | 300µm | 11 | 12nm | 0.1 | Chromatic |

| S13/1.1 | 1.1mm | 12.7 | 25nm | 0.1 | Chromatic |

| S16/2.5 | 2.5mm | 16.4 | 75nm | 0.1 | Chromatic |

| S29/10 | 10mm | 29 | 280nm | 0.1 | Chromatic |

| S20/20 | 20mm | 19.6 | 600nm | 0.1 | Chromatic |

| L25/2H | 2mm | 25 | 0.1µm | 0.05 | Triangulation |

| L35/10H | 10mm | 35 | 0.5µm | 0.03 | Triangulation |

| L50/20H | 20mm | 50 | 1µm | 0.03 | Triangulation |

| L70/50H | 50mm | 70 | 2.5µm | 0.03 | Triangulation |

| L270/70H | 70mm | 270 | 2.3µm | 0.01 | Laser |

The sensor naming convention is generally as follow:

First letter – S stands for Spectral (sometimes called chromatic or white light sensor)

First letter – L stands for Laser triangulation sensor

First number – i.e. 5, represents the distance from the target (stand off) in mm that the sensor needs to be at in order to take measurements

Second number – i.e. 2, is the measureing range in mm of the sensor

Hence, an S5/03 sensor is a spectral type sensor with a 5mm stand off and a 300 micron measuring range.

Other sensors are available. Please contact us for alternative ranges.

| Technical Sepcification | |

| Scanner overall dimensions (w x h x d) | 1130 x 600 x 450mm |

| Electronic cabinet overall dimensions | 315 x 705 x 600mm |

| Granite table size | 1130 x 600 x 70mm |

| X travel | 800mm |

| Electrical requirements | 100-110/220-240 VAC, 50/60Hz |

| Operating temperature | 10- 35 deg C |

| Step size (minimum) | 1µm |

| Step size (maximum) | 9.99mm |

| Data collection rate (maximum) depends on sensor & set up | 20,000points/sec |

| Scanning speed (maximum) depends on set up | 90mm/sec |

| Retrace speed | 100mm/sec |

| Maximum no. of data points | 2400 (option available to increase to 20,000) |

The Proscan 2D surface profilometer is at home in a number of settings and, with its array of measurement capabilities, it’s a versatile tool that offers a multitude of practical benefits, central to which is maintaining quality control and preventing delivery of sub-par products to customers.

- Rugged construction means the Proscan 2D can be used on the shop floor or laboratory

- Large 800mm scan

- A high speed of measurement means a complete scan takes just a few seconds

- With our very easy to use, dedicated measuring software, no special operator training is required yet provides a host of advanced analytical features

- Interchangeable non-contact sensors

- Full turnkey solution

This offline profilometer will scan the top surface of objects over a distance of 800mm. A graphical 2D representation of the scanned data will be shown on screen and by using the surface analysis tools the sample can be properly quantified.

A number of different sensors can be used with the Proscan 2D. This enables the end user flexibility to measure a wide variety of different materials with contrasting surface properties. Sensors with very small measuring ranges are often used on very smooth surfaces to determine true surface roughness. Sensors with larger measuring ranges are used more on surfaces where a profile has been produced and needs to be measured.

- Waviness on Gypsum board

- Flatness on sheet or board materials

- Surface profile of etched materials

- Flatness, roughness or bend in boards or bars

- Rapid shape measurement for large components