Extruline

Extruline online measurement with feed back

Extruline.XY and Extruline.X gauges by AEROL are designed for the extrusion industry to measure diameter and ovality online and regulate the extrusion process automatically.

They provide high repeatability and high resolution online measurement and process feedback for plastic, tube, hose cable and other extrusion uses. Typical applications include plastic tubing, mandrels, and electric cables.

Extruline is available in single or dual axis models for a variety of applications. The high accuracy of the system allows extrusion to efficiently regulated close to bottom tolerance, for rapid material savings. Optional software is available to detect flaws on the extrusion and relate them to spool position, making the Extruline a two-in-one system.

Diameter and Ovality Measurement

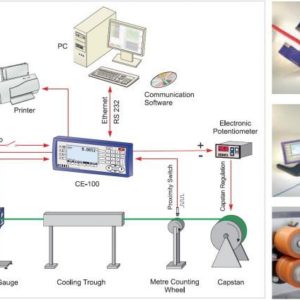

The Extruline online measurement with feedback system includes the new CE-200 operator interface panel, with colour-coded tolerance display and easy programming and product library selection.

- Diameter 0.1 to 149 mm, depending on model

- Resolution from 0.01 µm

- Repeatability from 0.02 µm

- Automated in-process regulation of extrusion head/capstan

- Metre counter input

- Flaw detection and location along the spool

- Optional statistical reporting on spools

- 100% quality control

- Efficient glass logic for transparent tubes or coated cables

AEROEL FEATURES

- 3-year warranty

- Low sensitivity to vibration owing to exceptional single scan repeatability

- Excellent dust resistance

- Easy-to-use product library with programmed tolerances

- In-built thermal compensation and self-mastering protocols

- Networking ability via Ethernet, even for multiple gauges, to a single computer program

- Data-logging with PC software

- Unique expertise – as a specialist laser micrometer manufacturer, Aeroel have unsurpassed know-how and experience in laser diameter measurement

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An EnquiryDownloads

| Dual Axis | ||||||

| Extruline | XY13/A | XY13/B | XY13/A/HF | XY13/B/HF | XY35/A | XY35/B/HF |

| Gauge Model | XLS13XY/480/A | XLS13XY/480/B | XLS13XY/1500/B | XLS13XY/1500/B | XLS35XY/480/A | XLS35XY/1500/B |

| Measuring field (mm) | 13 x 13 | 4 x 4 | 13 x 13 | 4 x 4 | 35 x 35 | |

| Measurable Diameters (mm) | 0.1 - 10 | 0.03 - 3 | 0.1 - 10 | 0.05 - 3 | 0.2 - 32 | |

| Resolution (selectable) | 10/1/0.1/0.01 | |||||

| Linearity (centred) (µm) | ±0.5 | ±1 | ||||

| Linearity (reduced field) (µm) | ±1 | ±0.5 | ±1 | ±0.5 | ±1.5 | |

| Repeatability (T=1s, ±2σ) (µm) | ±0.15 | ±0.03 | ±0.04 | ±0.02 | ±0.3 | ±0.15 |

| Beam Spot Size (mm) | 0.1 x 4 | 0.03 x 0.1 | 0.1 x 4 | 0.05 x 0.1 | 0.2 x 4 | 0.2 x 0.1 |

| Scanning Frequency (Hz) | 480(X) x 480(Y) | 1500(X) x 1500(Y) | 480(X) x 480(Y) | 1500(X) x 1500(Y) | ||

| Single Axis | |||

| Extruline | X40/A | X80/A | X150/A |

| Gauge Model | XLS/40/1500/A | XLS80/1500/A | XLS150/1500/A |

| Measuring field (mm) | 40 | 80 | 150 |

| Measurable Diameters (mm) | 0.1-38 | 0.75-78 | 0.8-149 |

| Resolution (selectable) | 10/1/0.1/0.01 | ||

| Linearity (centred) (µm) | ±0.5 | ±1 | ±3 |

| Linearity (reduced field) (µm) | ±0.5 | ±2 | ±4 |

| Repeatability (T=1s, ±2σ) (µm) | ±0.07 | ±0.2 | ±0.4 |

| Beam Spot Size (mm) | 0.08 x 2 | 0.4 x 3.5 | 0.5 x 4 |

| Scanning Frequency (Hz) | 1500 | ||

The basic package includes the following functions:

- Display of the measured diameter and of the shift from the nominal diameter

- Computes the (X+Y)/2 Avg. Diameter and (X-Y) Ovality

- 3 measured values can be simultaneously displayed on the screen

- Programmable alarms and pre-alarms for out-of-tolerance conditions

- Measurement of opaque or transparent products (Glass Logic)

- Library for 1000 different products, retrievable directly by the operator

- Possibility of entering a password to restrict the programming functions to authorised personnel

- Ethernet / Rs232 interface for remote programming or data retrieval

- Multi-lingual menus (Italian, English, French and German)

- Selectable measuring unit (mm or inches) and resolution

- Pre-programmed factory setup to facilitate installation and start-up of the system

The additional Process Regulation module (Option 1) features the following functions:

- Software for automatic regulation of the diameter by adjusting the drawing speed or the flow rate of the extruder

- The regulation parameter is the average diameter, which is independent from the cross-section orientation, even when highly ovalised products are being gauged

- PI (Proportional Integral) mode using INC (+) or DEC (-) signals

- The process regulation is started only when a real trend to deviate from the nominal pre-set value is detected

- Automatic compensation of dead time, according to variations of the line speed

- All control parameters can be programmed and stored in the product library

- Programmable hot/cold offset to compensate for the thermal expansion of the extruded product when the measurement is performed immediately after the extrusion head

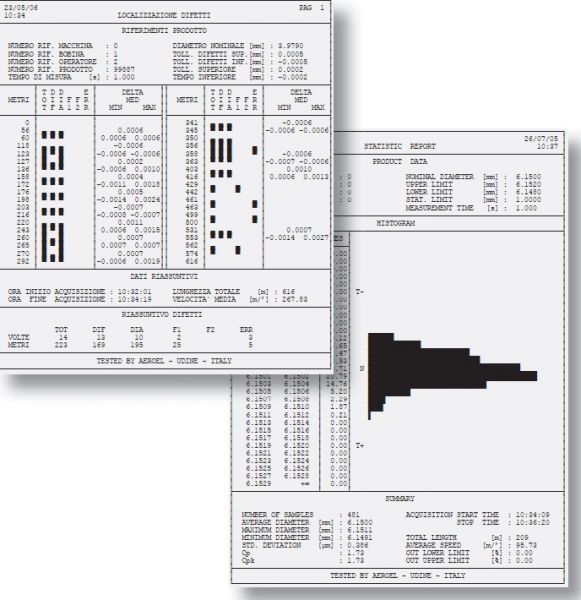

The additional Statistics module (Option 2) offers the following functions:

- Histograms showing the measured diameters: (X+Y)/2 or X&Y values

- Programmable diameter limits to filter out and ignore abnormal measurements arising from anomalous working conditions

- The data acquisition interval can be selected manually by the operator or automatically determined via a Start/Stop input

- Recording of maximum, minimum and average values

- Calculation of standard deviation of Cp and Cpk values

- Total length and average speed reporting

- All listings show the date and time

- Identification of the operator, the machine and the type of product

- Progressive numbering of the reel

The additional Flaw Detecting and Location module (*) (Option 3) offers the following functions:

- Single scan diameter checking capability

- Separate tolerance limits for the flaw detection function, added to the pre-set nominal value or to the average diameter previously measured (self adapting mode)

- Independent outputs for + and – flaws

- Recording of the max or min value of the flaw and its position along the spool

- Print out of a Flaw Location Report

- The report can include flaws detected by other external devices (i.e. Spark Testers, Capacitance Testers, etc.)

- Plastic and rubber extrusion

- Electrical wires and cables

- Tubes and piping

- Cable and wire

- Additional software for the extruder regulation

- Additional software for statistical analysis

- Additional software for flaw detection and location

- Electronic potentiometer for the extruder interfacing

- Proximity switch for length counting

- Blow rings to dry the product

- Telescopic stand for the laser gauge

- Extension cables

- Calumet exhaust fan to remove the extrusion smoke

- Gauge Calibration Report