Nuclear & Defense

Bespoke non-contact surface measurement for nuclear and defense

Scantron has a long, illustrious history of working in defense applications where tolerances are critical. Our products have been used throughout the nuclear and defense sector and with over 40-plus years of experience, we’ve also developed bespoke solutions for nuclear and defense projects.

Scantron products for nuclear and defense non-contact measurement

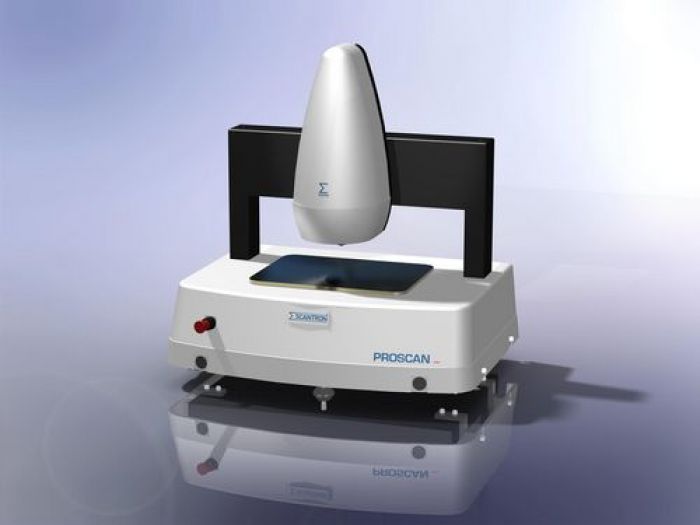

Scantron’s Proscan 2100 can perform rapid 3D scanning of surfaces down to sub-micron resolutions. This allows measurement of roughness, flatness, surface area, condition and defectivity, along with many other parameters.

Our DDMS system (Defect Detection Measurement System), along with other bespoke systems, was developed for measurements of thickness, roughness and defectivity on key components. DDMS uses a revolutionary AI algorithm to detect defects with a four axis scanning system.

The fine tolerances and small scale of defects intrinsic to nuclear and defense projects necessitate a robust approach to measurement. Scantron developed an intelligent vision system to identify and categorise defects, in terms of size and type, on metal or ceramic plates.

The development of bespoke systems for various defense applications is possible thanks to our considerable experience and expertise in this field.

Previous applications of Scantron non-contact measurement solutions for nuclear and defense partners have included:

• Measurement of radius, roughness and width of fine channels

• Dimensions, roughness of thickness of thin panels

• Automated location and inspection of pinhole defects

To find out more about Scantron’s bespoke systems for nuclear and defense applications, contact us.