SuperMeclab

Meclab high precision metrology stations for benchtop and offline measurement

In addition to Aeroel’s Meclab offline measurement quality control laser gauges, we also supply Super-Meclab.X and Super-Meclab.T all-in-one metrology stations for benchtop or offline measurement. They measure diameter for pins, turned parts, drawn wire, dies, wire, fibre or extrusions. They both feature a built-in PC with special software, a granite base and integrated controls, and linear slide with micrometer adjustments and positional encoder and read-out.

Working with the Super-Meclab.T high precision laser micrometer

The Super-Meclab.T (Tools) has additional software for measurement and characterisation of cutting diameter, concentricity etc. for samples such as drill bits, fluted parts, reamers, mills and cutting tools. Both gauges can be equipped with a motorised, counterweighted fixture to rotate the component for measurement of min-max diameter, roundness and run-out.

Through-feed mode makes measurement of multiple diameter positions simple, just by loading the product information from a library and pushing it through the measurement field.

- Diameter 0.06 to 78 mm, depending on model

- Resolution from 0.01 µm

- Repeatability from 0.07 µm

- Tolerance checking and display

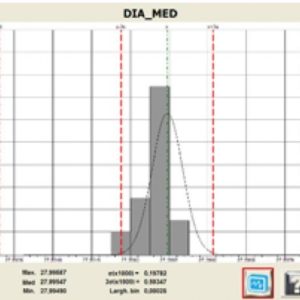

- Built-in statistical analysis package

- Measurement of run-out, multiple diameters, min-max, roundness and more with one instrument

- Vast range of accessories and fixturing available including v-grooves, dead centres, hollow cones, linear slides etc. with low friction coatings on contacting parts

AEROEL FEATURES

- 3-year warranty

- Low sensitivity to vibration owing to exceptional single scan repeatability and granite basing

- Excellent dust resistance

- Easy-to-use product library with programmed tolerances

- In-built thermal compensation and self-mastering protocols

- Data-logging

- Unique expertise – as a specialist laser micrometer manufacturer, Aeroel have unsurpassed know-how and experience in laser diameter measurement

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An EnquiryDownloads

| Type of Gauge | XLS40/1500/B | XLS80/1500/B |

| Measuring Field (mm) | 40 | 80 |

| Measurable Diameters (mm) | 0.06 – 38 | 0.75 – 78 |

| Resolution (Selectable) (μm) | 10 / 1 / 0.1 / 0.01 | |

| Linearity (Centred Product) (μm) | ± 0.5 | ± 1 |

| Linearity (in the Measuring Plane) (μm) | ± 0.5 | ±1 |

| Repeatability (T=1s, ±2σ) (μm) | ± 0.07 | ± 0.2 |

| Single Shot Repeatability (±2σ) (μm) | ± 1.5 | ± 3.5 |

| Beam Spot Size (s,l) (mm) | 0.06 x 0.1 | 0.4 x 0.2 |

| Side Dither of the Scanning Plane (mm) | ± 0.02 | ± 0.05 |

| Scanning Frequency (Hz) | 1500 | |

| Scanning Speed (m/s) | 300 | 588 |

| Gauge Thermal Coefficient (μm/m°C) | – 11.5 | – 11.5 |

| Laser Source | VLD (Visible Laser Diode); λ = 650nm | |

| Dimensions of the Basic System (mm) | 500 x 162 x 200 | 790 x 198 x 200 |

| Dimensions of the HP Version (mm) | 500 x 234 x 640 | 790 x 271 x 640 |

| Weight of the Basic System (kg) | 6 | 9 |

| Weight of the HP Version (kg) | 30 | 33 |

- No error due to the hysteresis (inversion error) which is typical of all dial indicator gauges (see QR-code video)

- Contactless measurement: no part damage or scratches

- Objective and highly reproducible results: regardless of the operator’s skill

- Extremely easy and quick to use: reduces inspection time and improves measurement capability

- Highly flexible: different components and sizes can be measured without gauge re-mastering

- Ultra accurate: it measures to an accuracy previously only found in a metrology room, using time consuming, expensive equipment and specialised personnel

- Fine measuring spot: you can measure details that would be otherwise impossible to detect

- Multiple measurements on the same part

- Multiple-point user re-mastering capability

- Quick tolerance check

- Zero-Set function

- Part library for easy programming

- Data recording, printing and exporting

- On line statistics and charts

- Digital oscilloscope

- NO-VAR technology: no measuring drift due to changing room temperature by programming the coefficient of thermal expansion of the part

The Super-Meclab.X and Super-Meclab.T were purposefully designed to act as a flexible gauge suitable for use across a range of applications:

- Electric motor shafts

- Ground or turned parts

- Gage pins

- Piston pins

- Hydraulic components

It measures diameter and ovality, run-out, edge position, taper, grooves or peak diameter, gap between parts and more.

The basic system (S version) consists of:

- XLS40 or XLS80 Xactum Intelligent Laser Sensor

- Flat granite baseplate with precision linear slide (400, 640 or 820mm long)

- Embedded Aeroel PC with 10.4” LCD monitor

- Super-Meclab.X software pre-installed in the system

- NO-VAR option: compensation of measuring drift due to changing room temperature

- Power supplies, connecting cables, keyboard and mouse

- Calibration report (available on request)

- Ready for external monitor (not supplied)

The SR version includes a motor driven device to rotate the part, with friction driving wheel and stepper motor.

Optional fixtures and accessories:

- Universal V block in hardened steel or insulated material

- Magnetic scale to read the slide position, resolution 0.005mm

- Pair of fixed V blocks (various heights) to be mounted along the slide

- Pair of free rolls (various heights) to be mounted along the slide

- Pair of centres to be mounted on the slide, at adjustable positions

- Set of 4 calibration pins for XLS40 micrometer, with supporting V block

- Device for fine tuning of the slide position, with micrometric head 0.5mm/rev pitch, ±6.5mm range