Profilab

Complete high precision measurement of multiple diameters and length for mechanical components

Profilab is an all-in-one metrology station for extremely accurate mapping of diameter and lengths for mechanical components. It comprises a standalone granite base and measurement cabinet containing Aeroel’s X40 laser micrometer, an embedded computer running special Profilab software, and motorised linear slide with precise adjustments and positional encoder and read-out for accurate part length measurements.

It is a complete solution and measures diameter, roundness and taper among other metrics, suitable for use across a range of turned parts. Ideal samples for Profilab include motor shafts, metal or carbide blanks, drill bits, cutting tools, or hydraulic components.

- Diameter 0. 3 to 30 mm

- Resolution 0.01 µm

- Repeatability 0.1 µm

- Tolerance checking and display

- Built-in statistical analysis package

- Measurement of run-out, multiple diameters, min-max, roundness and more with one instrument

- Vast range of accessories and fixturing available including v-grooves, dead centres, hollow cones, linear slides etc. with low friction coatings on contacting parts

AEROEL FEATURES

- 3-year warranty

- Low sensitivity to vibration owing to exceptional single scan repeatability, cabinet and granite struture

- Excellent dust resistance

- Easy-to-use product library with programmed tolerances

- In-built thermal compensation and self-mastering protocols

- Data-logging

- Unique expertise – as a specialist laser micrometer manufacturer, Aeroel have unsurpassed know-how and experience in laser diameter measurement

Scantron supplies a wide range of Aereol products and can develop bespoke systems for high precision measurement. Contact us to find out more.

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An EnquiryDownloads

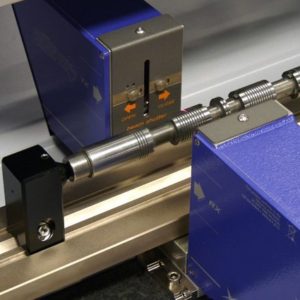

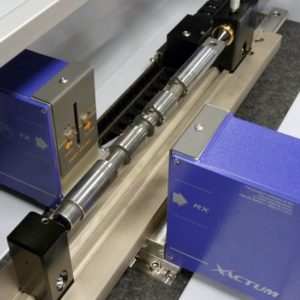

The Profilab system uses an Xactum high speed, high accuracy Laser Micrometer to measure the diameter and the edge positions of the part, which is mounted on a motor driven slide and moved by a linear motor; the slide is fitted with a digital linear scale to read the longitudinal position of the sample.

To assure maximum accuracy and stiffness, the slide is aligned and mounted on a flat granite base. The part is moved to the measuring positions, following a pre-set “measuring program” stored in the computer memory. It is also possible to rotate the part, in order to get roundness or run out at any given position.

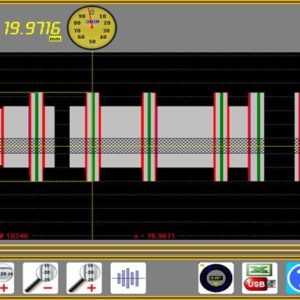

By using suitable fixtures and by processing the diameter, the edge positions and the longitudinal displacement information, it is possible to check several dimensions, on a number of different parts. The measured data is processed by a PC with integrated touch sensitive 19” TFT screen; the provided software comes with an extremely friendly user interface. The software is “locked” and self-starting so the operator will have the program running immediately (not starting from Windows!)

- Programming and storing of several “measurement programs”

- Selection of different measurement types and modes, at each measuring position

- Multi language menu and inch/mm display

- Multiple tolerance check

- Part library for easy set-up and quick part change-over

- On line statistics and report print out

- Data recording and exporting

- Multiple-point user re-mastering capability

- Wide measuring field: 40mm

- Measurable diameters from 0.3 to 30mm

- Linear range of the slide: 300mm

- Linearity: diameter ± 0.5μm length ± 5μm

- Repeatability: diameter ± 0.1μm length ± 3μm

- High scan frequency: 1500Hz

- Longitudinal displacement resolution: ± 1μm

- Maximum displacement speed: 500mm/s

- Permanent self-calibration

- Self-compensation of the thermal drift due to changes in the ambient temperature

Several accessories and fixtures are available to hold and position the parts being measured, such as two V blocks, two dead centres or cones, two couples of precision free rollers, motor driven centre + live centre, etc. all adjustable in position along the slide table and following the specific application requirement.

Some benefits include:

- Automatic work and highly reproducible results regardless of the operator’s skill level

- Extremely easy and quick to use, reducing inspection times and improving measurement capability

- Highly flexible, allowing different components and sizes to be measured without system pre-setting or re-mastering

- Ultra accurate laser technology means you can measure to accuracy levels that previously could only be produced in a metrology room, using much more expensive equipment and specialised personnel

The PROFILAB.X40 System is an automatic laser measuring station, useful to check a wide range of turned or ground parts such as:

- Motor shafts

- Hard metal blanks

- Drill bits

- Cutting tools

It measures diameter, length, roundness, taper and run-out of cylindrical sections, effective cutting diameter of fluted cutting tools, and straightness of hard metal blanks.

Multiple options available – eg. Part holding