Meclab Tools T40

Bench-top Laser Micrometer

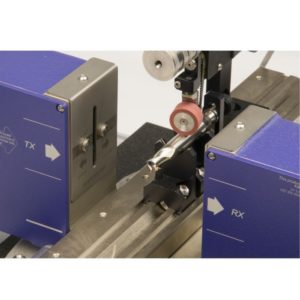

MECLAB.T40 is a high precision laser instrument for quick and simple diameter measurements of hard metal blanks and full carbide cutting tools with odd or even edges. It provides offline measurement of diameter, run-out, roundness, min-max and cutting diameters for fluted tools, blanks and bits.

It’s ideal for the offline checking of:-

- Drill bits

- End mills

- Reamers

- Cutting tools

In addition it can be also used to check the diameter, ovality and straightness of:-

- Hard metal blanks

- Ground pins or cylinders

This bench top laser micrometer doesn’t require a PR. That makes it ideal for use in the workshop. It can be placed close to the machine to generate accurate diameter measurements quickly and simply. It is also very cost-effective, which makes it an attractive diameter measurement option for smaller operations.

Ease of use and high repeatability

The MECLAB.T40 bench top laser micrometer uses a guided process, with the operator positioning the part at the start position and then choosing manual or automatic rotation. The laser scans at the rate of 15000 samples per second while the software provides accurate and repeatable measurements of cutting diameters and run out for odd and even fluted parts.

Accurate and flexible it can be used as a bench top flexible gauge across many shapes and sizes of pieces including hard metal tools and machined parts.

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An EnquiryDownloads

| Xactum XLS40/1500/B Laser Micrometer | ||

| Measurable Diameters | (mm) | 0.06 - 38 |

| Linearity (Centered Product) | (μm) | ± 0.5 |

| Linearity (Full Range) | (μm) | ± 0.5 |

| Repeatability (T=1s, ±2σ) | (μm) | ± 0.07 |

| Single Shot Repeatability (±2σ) | (μm) | ± 1.5 |

| Beam Spot Size (s,l) | (mm) | 0.06 x 0.1 |

| Scanning Frequency | (Hz) | 1500 |

| Gauge Thermal Coefficient | (μm/m°C) | -11.5 |

| Meclab.T40 System - Manual Version | ||

| Dimensions | (mm) | 500 x 630 x 237 |

| Weight | (kg) | 30 |

| Meclab.T40 System - Automatic Version | ||

| Dimensions | (mm) | 518,5 x 630 x 290 |

| Weight | (kg) | 39 |

There are many features to the MECLAB.T40 benchtop laser micrometer for diameter measurement.

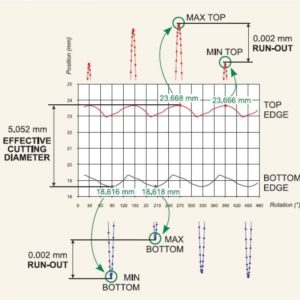

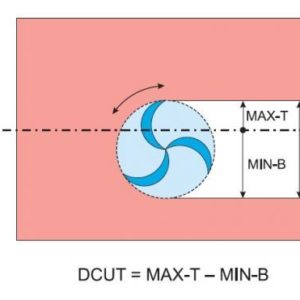

Using the tool dedicated menu, it is possible to check full carbide tools with ODD or EVEN cutting edges. The measurement mode must be On-Command Continuous and the part must be rotated (manually or automatically) to detect the max and min positions of the Bottom and Top edges. In this way the software measures the tool diameter DMAX (EVEN edges only), the Effective Cutting Diameter DCUT and the RUNOUT.

The RUNOUT is calculated as the maximum swing of the peak position of all the cutting edges during

- Multiple language pop-up menus for easy set-up and programming

- Display millimetres or inches

- Automatic seeking of the “zero point”

- Reading the slide position

- Quick change over of the cutting edge number

- Display of 3 measured variables

- Quick tolerance check and alarm outputs

- 1000 parts library for quick programming

- I/O Lines for Easy Interfacing and start/stop input for a foot switch

- Connection to a PC and easy Excel interface

Fast measurements of the following products:

- Drill bits

- End mills

- Reamers

- Cutting tools

- Hard metal blanks

- Ground pins or cylinders

DIA = Average Diameter

DDIA = Deviation of the average diameter

CEN = Average position of the centre

DCEN = Deviation of the average position of the centre

POS = Linear encoder position

T-AM Estimated ambient temperature

MIN-D = Minimum Diameter

MAX-D = Maximum Diameter

DMIN-D = Deviation of the minimum diameter

DMAX-D = Deviation of the maximum diameter

RNG-C = Range of the centre position

MIN-C = Minimum centre position

MAX-C = Maximum centre position

DMIN-C = Deviation of the minimum centre position

DMAX-C = Deviation of the maximum centre position

The Automatic version includes in addition:

- Motor driven device to rotate the part, with friction driving wheel and stepper motor

- Equipped base, mounted under the granite base containing the electronic driver for the motor

Common Options:

- NO-VAR software option for the automatic self-compensation of the parts thermal expansion, by programming its thermal expansion coefficient

- GageXcom Software for data transfer to Excel